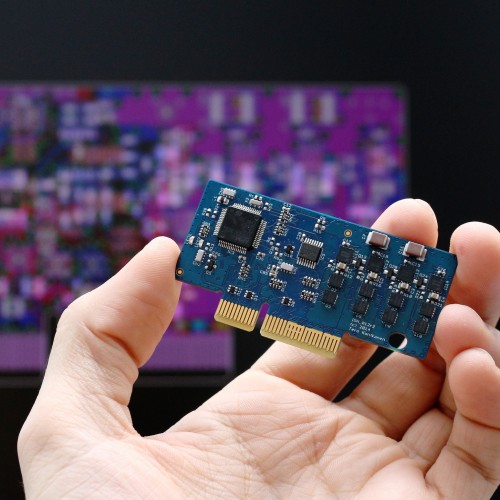

The testing protocol of IONI drives is derived from Argon test setup and consists several steps including:

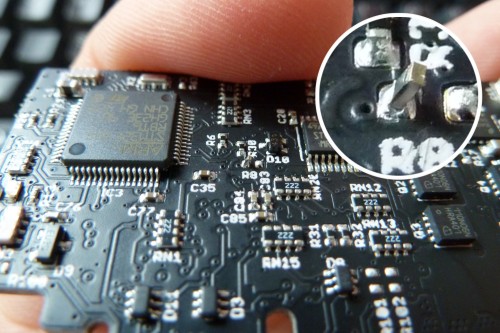

- Chip programming and program verification

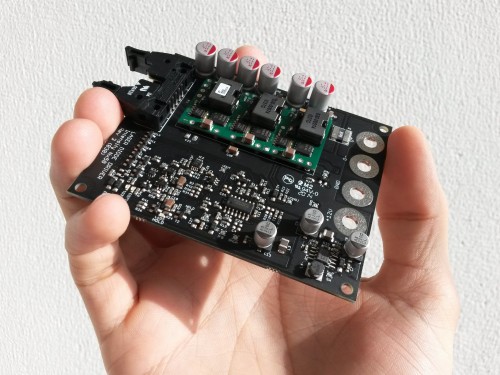

- Testing of digital inputs & outputs

- Testing accuracy of analog inputs (analog setpoint input as well as on-board sensor signals)

- Testing interconnectivity of internal circuity

- Testing all electrical functionality (such as safe torque off)

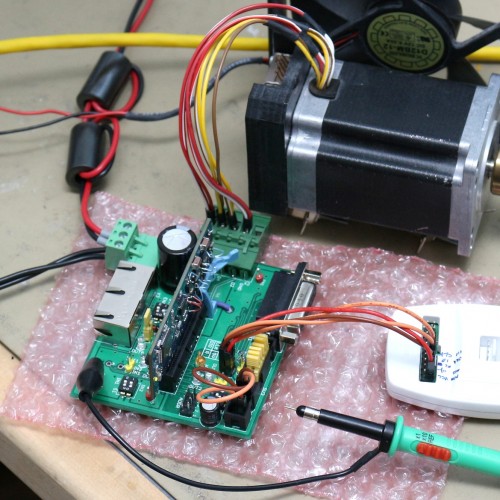

- Burn-in testing with maximum load. The load is a large stepping motor which utilizes all four power stage channels.

- From burn-in data, we measure time versus heating (efficiency) and torque control behavior

- All results, data and logs are stored in SQL database where we can look for anomalies if a device fails later