In the beginning

I have been developing motor drives since 2006 and the first development project was a cost efficient implementation of AC/Brushless servo drive that would suit in CNC machine applications (another hobby of mine). The outcome was so promising that we (I and my colleague, Timo Piiroinen) decided to start a company to manufacture and sell them. To see details about the first drive, follow this link to my old hobby web site. The first drive was called VSD-A (Versatile Servo Drive) and it was sold at 2007. The most significant contributios of VSD-A:

- 1 kW sinusoidal AC servo motor drive with excellent cost efficiency

- Encoder feedback with pulse-and directio reference input

- Wide supply voltage range of 12 to 200 VDC

VSD-A drive

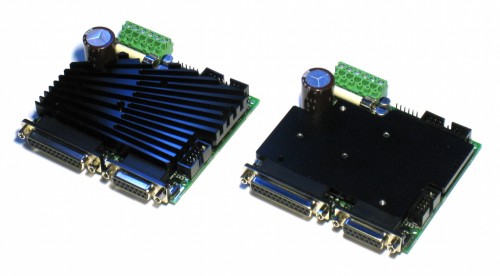

New ideas didn’t stop coming into my mind, so soon after VSD-A I started planning the next drive. The direction of development was to add more sophisticated features, power, ruggedness in a smaller package. One of the design innovations were the card form factor that is easily installed inside a cabinet with holes for D-sub connectors that reach out of the box without any intermediate wiring. The another very significant innovation was a DualDC operating mode where single drive could control two independent servo motor axis. The outcome is called VSD-E where E stands for Evolution. VSD-E is still in production and will continue to be produced as long as it has enough demand. The significant contributions of VSD-E:

- Elegant design allows installing inside cabinet like PC expansion cards

- Supports most of AC/BLDC and DC servo motors while keeping affordable price

- Voltage range of 12-160 VDC and power up to 2 kW

- Single drive can also drive two independent DC servo axis

- Protected against various fault cases (short circuit etc)

Listening the Customers

After selling numerous amounts of VSD-E, we have got lots of feedback and discussion about topics like setup and desired features of a “dream drive”. In no time a new drive started forming in my mind. Some most important things that we felt we need to change about VSD-E:

- Form factor – no matter how much we love the VSD-E’s form factor, in many cases it was easier to install traditional enclosed/boxed drive inside cabinet than a card type drive. This time drive should be wall mountable box instead of a PCB card.

- Connectors – the new design should have pluggable screw terminals to easily connect large motor leads

- Supply voltage – to eliminate the need of external AC to DC power supply unit, the drive should directly accept AC mains voltage as supply. This adds some cost but it will in total save money as external PSU isn’t free either.

- Connectivity – in some cases users find the I/O’s of VSD-E limiting (such as no 24V signals can be fed to it without external resistor). This time we extend I/O voltage range to include the standard 24V while same time increasing number of I/O’s. Now there is enough I/O for dedicated axis limit switches.

- Monitor & setup – the new drive should be able to communicate simultaneously to configuration & monitor software tool while drive is being used by the actual application (such as CNC controller).

- Field bus – the drive should have a field bus connectivity for those who don’t prefer to use old school reference signals (step/dir, analog, etc).

- Sensitivity – the drive should be hardened against virtually any amount EMI interference. The new design should have more configurable fault tolerance levels to adapt better in difficult environments (such as arc welding machine).

- Flexibility – VSD-E (as any other drive on market today) has fixed functionality. Users are able to configure it to behave different ways, but not able to do much outside the predefined set of functions. The new drive overcomes this limitation by incorporating “user CPU” that can run user code. User CPU allows implementing stand-alone controls as well as additional I/O and feedback support.

- Safety – one of the most missing feature in the motor drive products in general. The new drive should have built-in functionality for safety stopping with various ensured motor stopping mechanisms.

- Setup – the setup & diagnosis software should be 100% rewritten from ground up. Amount of confusing parameters need to be minimized while preserving functionality.

It does it all, then it does more…

The upcoming drive has been named as Argon. The original plan was to call it VSD-R after Revolution. However the name didn’t sound revolutionary enough to justify the significance of the design changes. Argon practically means the rebirth of the whole business for us, and hopefully even more for the customers.

The outcome

Argon servo drive hardware design has been finished on August 2013 and devices are now in full production. Argon is being used in multitude of applications, including robotics, CNC machine tools as well as professional grade force feedback systems (i.e. racing simulators).

More about Argon:

- Argon Product page

- Wiki page (product details)

- Full specifications (electrical specifications)

- User guide

- Support (ask a question about Argon)

Argon is available world wide through Granite Devices web shop as well as many of Argon distributors.

I’m very much looking forward to the new drive, and already have a couple of projects lined up for when it’s released. Having said that, I intend to keep using VSD-E/XE as long as it’s available, unless you replace it with a similar product, as the form factor and features work really well for us. I hope it stays in production!

What would it take to build the VSD-XE to allow higher current operation – thicker copper on PCB? Uprated components? Is this possible or practical? Any increase would be useful, but if we could get to 40-50A peak that would be ideal.

Kind regards,

Jason

Jason,

VSD-E series will continue in production, however, of course not forever. After Argon is ready we start working with Ion and see if there is still demand for VSD-E’s. If there is, then updated model of VSD-E probably will follow (or just larger Ion) and it actually may have the capabilities that you hoped for (higher current traded with lower voltage as >100V range is better covered by Argon).

Changing VSD-E to high current should be technically no problem. Biggest change may be thickening the PCB traces. Other changes would be different type MOSFETs and lower value current sense resistors.

Really awesome post, highly beneficial and expertly written.. Good Activity

For this great job you are doing – thank you very much – and a happy New Year !

Looking good Tero, keep up the good work!

It’s really a great and useful piece of info.

I’m satisfied that you shared this useful information with us.

Please stay us up to date like this. Thank you for sharing.

I am interested in purchasing this drive for a project but I can only find it for sale in Europe. Do you have distributors in the US. Please contact me to discuss. Thanks!

So, many interesting facts and critical instances that I’m astonished and highly satisfied with the information you give us.

The matter is burning as well, so I suggest I will read it two.

The article is clear and bright, with no additional worthless details or else.

The speech is equally brilliant and brilliant, so the further I read, the

more I do enjoy it!

The article shows some burning issues and questions

which needs to be discussed and clarified. What’s more, it is vital to comprehend within the detail.

From the post, one can easily find something fundamental, remarkably for him/her, something which

will be extremely helpful. I am thrilled with the information I’ve just obtained.

Thank you a lot!

I bookmark these pages right a way! Thanks a whole lot to this author for this

a fantastic post. It educated me about https://ESSAYWRITENOW.COM SAME

DAY ESSAY SERVICE , I think that your blog is at least as great

as theirs. I will certainly get back to your own page to see new

posts in the future! Good luck!