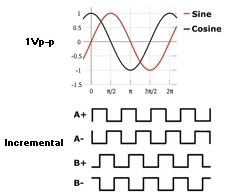

Something cool is under development relating to BLDC (brushless DC) motors. BLDC is similar technology to sinusoidal AC motors but with trapezoidal voltage waveform. This makes BLDC little bit smaller and usually cheaper than AC motor.

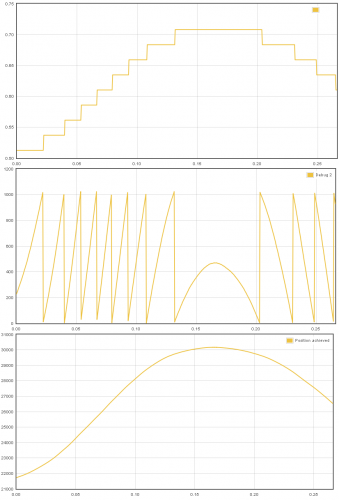

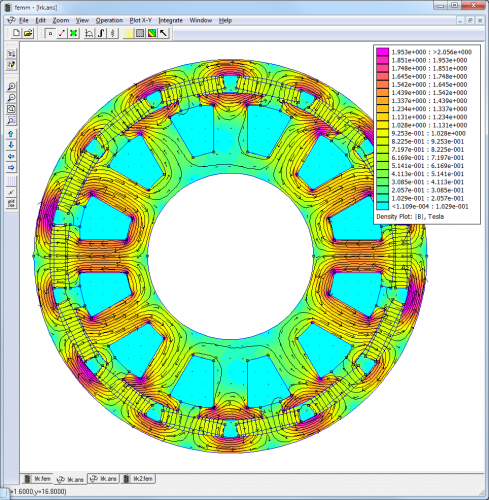

While I’m typing this, in running a FEM simulation of outrunner BLDC motor to optimize the electrical commutation phase angle for such motor. Iterative simulation takes some 20 hours to compute.

Finding optimum commutation angle makes it possible to implement MTPA (maximum torque per amp) drive algorithm for such engines. Such efficiency boost might be very beneficial especially in battery powered applications such as multicopters, but of course it also will benefit squeezing more out of the existing motors. More about that later!