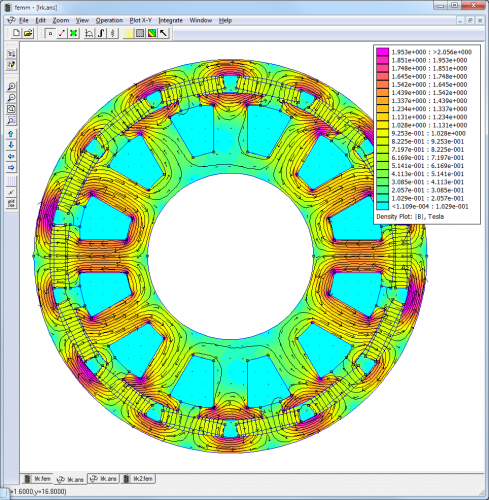

Development today focused on improving torque smoothness of motors. Some motors, especially cheaper ones and stepping motors, suffer from cogging torque:

“Cogging torque of electrical motors is the torque due to the interaction between the permanent magnets of the rotor and the stator slots of a Permanent Magnet (PM) machine. It is also known as detent or ‘no-current’ torque. This torque is position dependent and its periodicity per revolution depends on the number of magnetic poles and the number of teeth on the stator.”

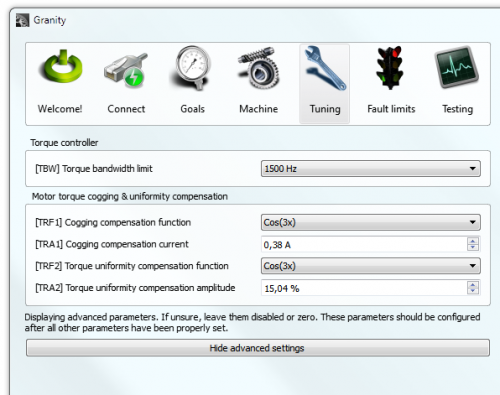

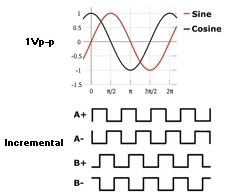

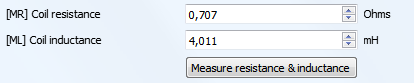

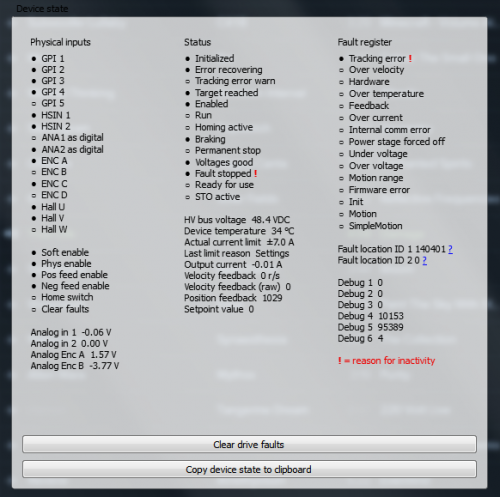

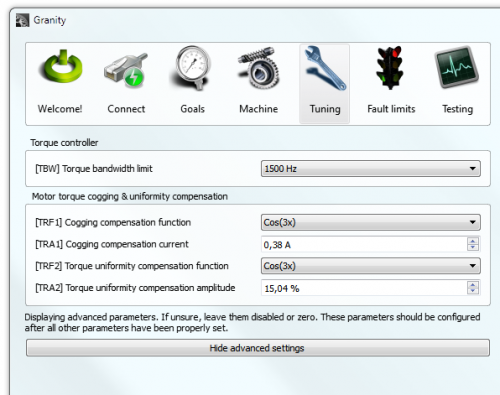

This can be compensated by modulating motor current to counter the motor cogging. The firmware under development adds options to adjust compensation current by few new parameters.

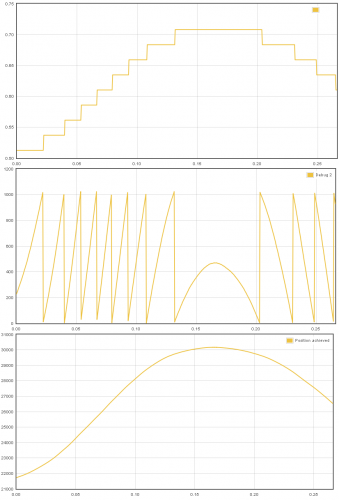

Perfecting motor with cogging and uniformity compensations

In addition to cogging torque, the new feature allows compensating also nonuniformity of torque production. I.e. if motor torque setpoint is kept constant and motor is being turned, it may produce variable amount of torque due to same reasons than cogging. Nonuniformity compensation will modulate the torque setpoint by a selected sine or cosine function and amplitude.

The new feature beta will become available for IONI Pro in the soon upcoming FW release. We hope that this will bring cost of any motor control system down as cheaper motor could achieve nearly same smoothness as expensive ones.

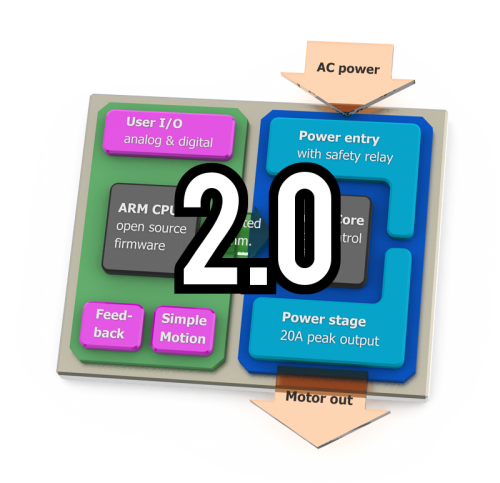

Curious to learn what’s inside in the top-tier servo drives? Want to put your ideas in motion? Are you a natural born microcontroller hacker suited for the job?

Curious to learn what’s inside in the top-tier servo drives? Want to put your ideas in motion? Are you a natural born microcontroller hacker suited for the job?