I’m at the point where I can’t think of any improvements to the hardware, so the order of first production run to factory will happen this week! The first patch will be split to two: smaller test run and followed by full production after all changes are verified to be good.

Last changes done

The last significant change made was to replace standard Y2 safety rated filter capacitors to every-possible-way-superior Murata surface mount Y2 capacitors. Not because design would not pass EMI compliance or there would be any problem with the standard type, but merely because I like the improvement!

Murata SMD Y2 filter capacitor

Standard Y2 filter capacitor

The self resonance frequency of typical 4.7 nF leaded capacitor occurs between 20-25 MHz while the SMT type has it around 90 MHz. This yields significantly more effective EMI noise filtering which was confirmed by oscilloscope measurements.

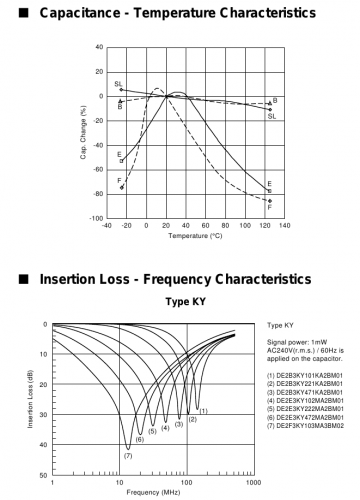

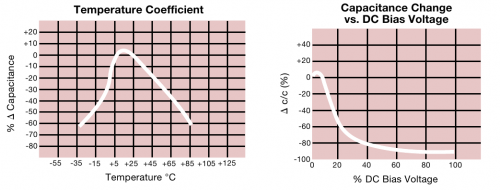

The new cap has also much better temperature and voltage stability characteristics. All available 4.7 nF leaded type capacitors tend to have bad temperature characteristics (curves E or F in the picture below, notice -80% change of capacitance at extreme temperatures) while capacitance of the SMT type nearly stays flat over the whole temperature range. Same kind of capacitance change does not only occur with temperature but also by voltage applied to capacitor.

Capacitor temperature characteristics (top) and impedance vs frequency curves (bottom). The self resonance frequency is at the dip seen in bottom curves.

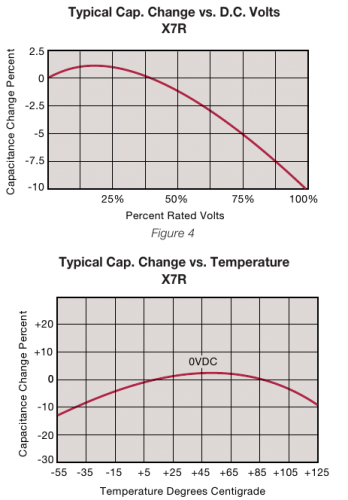

The above actually applies to all ceramic capacitors. Luckily the temperature & voltage characteristics have standardized naming so staying away from poor types is easy. Cheap ceramic capacitors are mostly called Y5V or Z5U capacitors while good caps know names such as X7R or NP0. Argon comes only with X7R or better types.

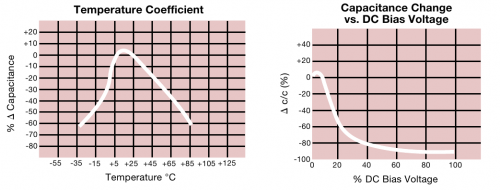

The horrors of common Y5V ceramic capacitor. Take for example a 35 volt Y5V capacitor and put 24V in it – capacitance decreases 90% from the specified value while ideally it should not change at all.

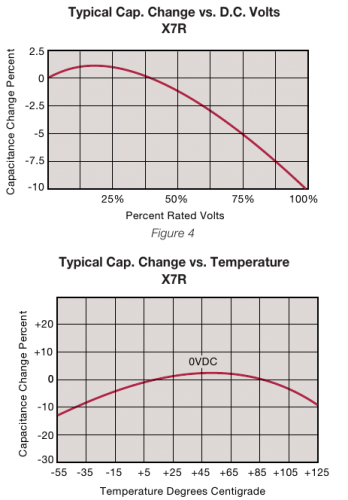

X7R characteristics. The worst case capacitance change stays within +/- 15%.

Back to the topic – the only downside of the SMT Y2 filter capacitors is the 4X cost compared to the standard type. However after all the total price difference isn’t huge as there’s only 3 pcs of them in Argon.