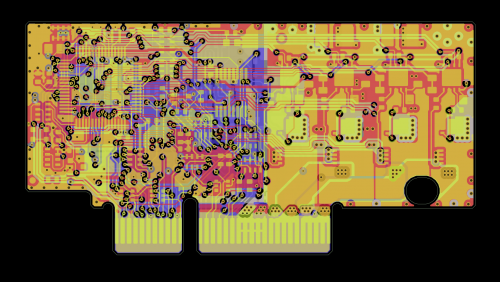

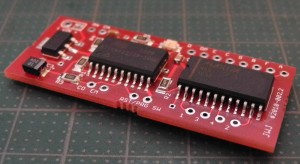

As we are expecting the release candidate prototypes of IONI arrive any moment now on the first week of December according to factory, it’s good to shed light to the plans regarding the drive.

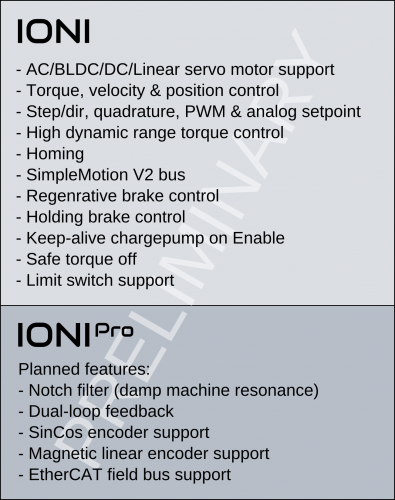

Here is a draft of one option: we launch a standard model which has all the features we have implemented to the date (pretty much all the stuff that Argon has) and a Pro version where we add sophisticated features that may be useful for the most demanding applications.

One might wonder why not to put everything into the one model. The reasons for separating the models into different price versions traces back to the cost. There will be cost of development and support that affect the Pro version price. Support is the main factor here. More sophisticated features inevitably generate more support overhead and that costs our time. If a customer buys lots of drives, then price of the two will become nearly same as the difference in support becomes near equal.

And the good news for early birds: as the implementation of Pro features will begin after standard IONI model launch, and there is no much extra in Pro, the early bird users will be receiving the Pro version at the price of standard model :-)