Yesterday was a day full of sparks – electrostatic discharge sparks. Tests were done by shooting sparks to to different targets including cables, casing and open connectors while the drive was operating. Also various ESD types were tested: contact discharge, air discharge, varying voltages and different polarities. All ESD tests were passed without a single hiccup.

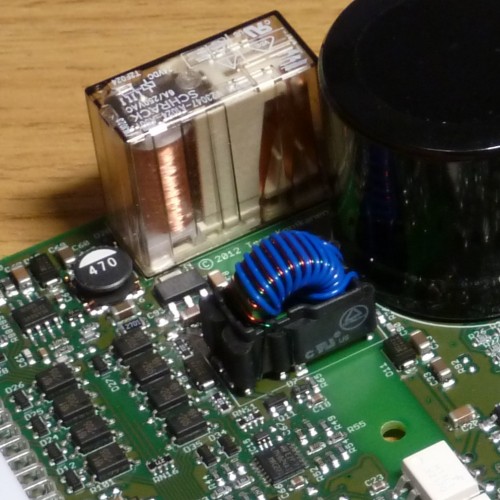

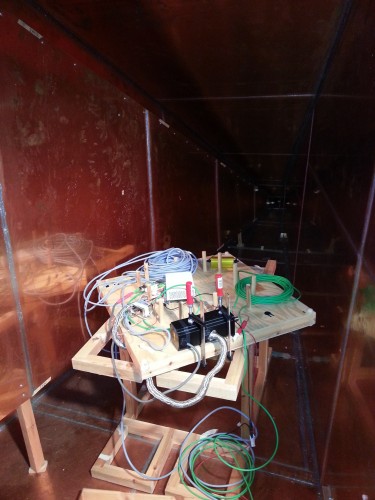

ESD test table and ESD gun

However, ESD is only one mode of high voltage harassment drive must cope with. Another test type is EFT (electrical fast transient) which is induced to cabling through capacitive clamp. Several kilovolts with nanosecond scale rise times were injected as 75 spike bursts into the clamp at frequency of 5 kHz and repeated 10 times. This simulates interference spikes emitted by nearby sparking or EMI. No problems recorded.

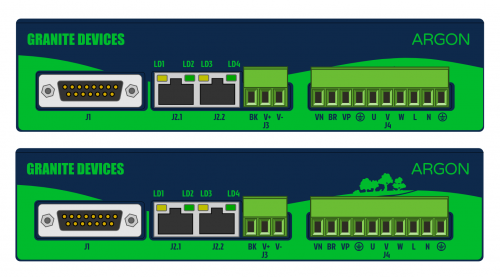

Encoder cable going through capacitive EFT test clamp

The last test was a surge test. A high energy and relatively long pulse were applied to supply voltage inputs. This is typically the most difficult harassment to filter out in electronics.

Surge & EFT test equipment – above is the 24V PSU and the device below is the EFT & Surge injector.

Difficulty of surge may be imagined by the funny fact that cheap lab power supplies tend to die during the test even when it’s not the target. So heavy duty PSU had to be used as supply to avoid it breaking.

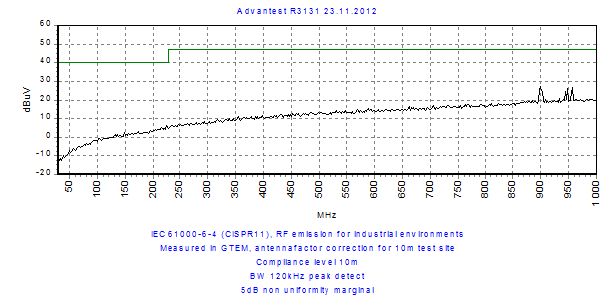

In this test we found a problem. The voltage regulator of Argon died when shot with 400 V and ~40 A pulse in negative polarity to 24V input. However, drive survived a 500 V positive polarity surge. 500 V is the required level to pass the test. Failing one tests means that some circuit/layout changes has to be done to address the problem.