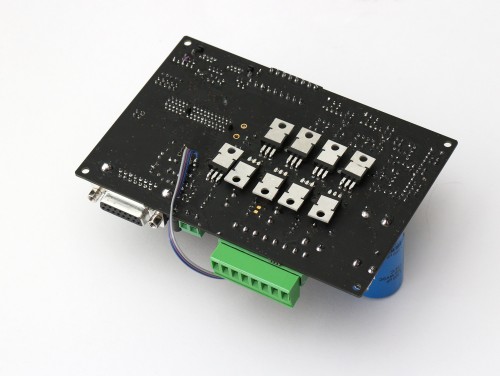

We have been quietly experimenting on a special IONI motherboard that has discrete power stage to extend IONI power capability. We already have a proof-of-concept board that is equipped with leftover VSD-E mosfets (61A 200V rated). After couple of weeks of use, we could not tell the difference between integrated and external power stage by observing motor control performance and smoothness.

IONIZER has been considered to be available as DIY board (bare PCB) and a reference design where users could modify it to match virtually any power need. However, it’s not ready and many changes are needed to have our approval (such as galvanic isolation of all I/O, short circuit protection and switch to PCI-E 8x socket for newer IONI). Finishing this might be a subject for another crowd funding project.

Some pros are:

- Can be made to virtually any power

- Not highly expensive

And cons:

- If built with assembly errors, can be hazardous

- Some safety & protection features add complexity on circuity (STO, over temperature & short circuit protections)

- Industrial manufacturing may not be cost effective (more complex solution than Argon)

Tell me in the comments how useful do you see IONIZER and which voltage & current range would be your preference :)

Ok, I admit that this is one thing that I wasn’t expecting, but I like the idea :)

>2 Kw it should be great. 4Kw seems enough for most applications and is the kind of power that I like to see on a cost effective board.

Dual dc motor control since you have 4 lanes seems to be a good feature to.

João

Yes, driving two DC motors would be possible with 4 power lanes but there is no enough other I/O on IONI for that (such as encoder inputs). So that is unfortunately out of question.

Great idea!

To be useful to me, it would need to be a finished board – I haven’t the time to spend putting together individual components, although I do understand others may have the time and skills. I’d be using it as part of a commercial product where almost all the electronics are a Granite Devices parts, so it would be a big advantage to me if it were supplied assembled and tested like the drives are.

Will it be limited to the same voltage range as IONI? I’d like 60 amps peak please!

For the machines I build argon is a little bulky, and I don’t need the enclosure so this looks really attractive. If the voltage is not limited to IONI’s spec, then the ability to connect 230 VAC would be very useful.

I’d be in for supporting another Indigogo campaign

Thanks for your thoughts!

No it’s not limited by voltage or current. In ideal case we would see third party manufactured power stage boards and many variations.

I’m thinking that maybe we could do this by the help of community (designing boards & making prototypes).

A set of open-source reference boards is an exciting idea. Similar to dirty pcbs (http://dirtypcbs.com/view.php) where

– anyone can order previous designs outright,

– or make some modifications, and order the modified design while making it available to others.

except all source files are available.

A github for IONI mother boards, if you will…..

That sounds good; something like that would work for me if I can locate a service or person to assemble them…

Regards,

Jason

Is this something we could add to Ioni to ease the design/assmbly of a high power drive, or am I way off track?

http://www.mitsubishielectric.com/semiconductors/content/product/powermod/powmod/intelligentpmod/highspeedswl/pm600cla060_e.pdf

Thanks,

Jason

I would be interested in finished boards, 230VAC if possible. Can’t help you with design but I would be interested in chipping in to finance it.

Also, is this going to be multi axis or single drive board only?

That would be single axis.

I believe for 230VAC the Argon drive would much easier solution. The custom board would be good filling the void of other voltage/current ranges.

Do you mean it could only be single axis, or that you had only planned it for single axis?

I’d like to see a multi axis hybrid of Ionicube and Ionizer. The use cases I can see include CNC machine tools with small axis drive motors and a large spindle drive, or robotics where there may be a couple of big drive motors and smaller motors for steering or onboard accessories but all motors would use the same bus voltage.

I’d also be interested in chipping in to finance it, but couldn’t be any use in the actual design.

Regards,

Jason

Sure it’s possible to fit multiple axis on one PCB but that would grow big. The single axis alone is 160×100 mm.

If we want to manufacture these industrially, we would rather make “powerstageless ioni” which would reduce parts from the power board and make them smaller. But that of course needs volume to be cost efficiently doable. Maybe there is enough demand for such systems, we will keep eyes open to spot it :)

I would love to have a reference design on which to base my own boards.

same here :)