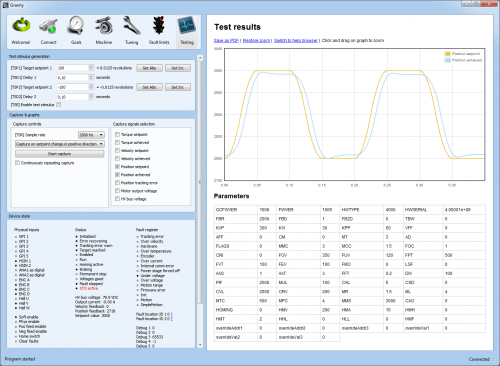

Granity got updated, already! Many of it’s new features are inspired by an excellent user feedback. The changes are:

- Set Abs and Set Inc buttons to change setpoint manually

- Display list of all parameters together with graphs – becomes useful when saving graphs as the list of parameters gets included in the file as well

- Safe Torque Off status is now displayed

Get the latest version here.

Keep the feedback & ideas coming! Fixing the found issues and making important improvements is the first priority for us.

tero

an idea for the zip file, included in the file GranitySoftware.zip the minimum firmware to use the downloaded version GranitySoftware

or added into granity a specific menu listing all firmware versions

Good points! I’ll add latest FW on the next release. Granity already has functionality that will notify user when connecting to a device if important FW updates are available.

during a firmware update, the parameters already present in argon PID, current Max…

they are preserved or zeroed / default value ?

if they are not preserved as it is very interesting Granity created a backup file settings before updating

to restore them after the firmware, writing, and keep a copy at the time of the update

Yes, factory default settings are restored on FW upgrade and user should save/load settings manually to preserve settings.

I put it on the list of ideas here: http://granitedevices.com/wiki/Granity

hi tero

Today I wanted to give it a try with argon

but when I connected the USB adapter SMV2 windows asks me for a driver instalation which is normal but no driver is found and remains unusable

is there a link where we can download the driver?

computer with Windows XP and not connected to internet

thanks

Hmm, apparently XP doesn’t come with suitable driver. Download a driver from: http://www.ftdichip.com/Drivers/VCP.htm

Later Windows versions shouldn’t need driver installation.

thanks

I will retry tomorrow

I would suggest, if possible, to add in the granity status the current temperature (even low frequency update is fine).

This can help the installer to know if it needs extra dissipation or forced dissipation.

Also I noticed that when the drive have a error, you added the ‘?’ sign in version 1.0.1 that is a link to a web page with the error list. Filling the error list (that you already have made, I presume – so not difficult or time comsuming) would be a great help.

Still regarding temperature, why not allow the user to define the over temperature value? If you know that is safe to operate the drive until lets say 70 ºC; you can allow the user to set the value until 70 ºC, it suits the manufacturer (you) and it suits the user.

Notes taken and inserted to the feature request list! Good ideas.

The error code list will be filled some day soon.

hi Tero

I’m in a misunderstanding for position control and torque

for the position I have encoder feedback that’s ok

but the couple I need a torque sensor?

doc wiki for setting the control position speaks of MR and ML used to adjust the torque control

I do not understand how it should process for setting

must procdédé in twice?

1 setting for the control torque (with a torque sensor?)

2nd setting for the control position

for information, I want to controlling the motor position

Maybe I can reply and help.

Torque tuning should always be made, if you control after in position mode or velocity mode. In ultimate analysis, you will always want that the motor achieves the desired torque, both in velocity and position.

AFTER you manage to have a good torque response, you should tune the position. That is all.

For torque tuning, you just need to clamp your motor (do not allow the shaft to rotate). The drive will then know if it was able to output the desired Amps in a controlled way.

I hope I helped.

ok thank you I have already informed you about the importance of adjusting the torque,

because if I understand it is thanks to the torque that I could keep an accurate position.

but as an engineer I would like to understand how the argon

can measure the torque on the motor shaft without sensor

The torque is directly proportional to the Amps, so the Argon knows the Amps +- equal to know the output torque. You can check the output graph, it is in Amps.

Good answers! +1

yes I know that the current is directly related to the torque on the motor shaft

but I perceive that I forgot to mention my motor is a permanent magnet DC Brush to

in this type of engine torque depends current in the coils but also magnets

Johann, its not different in DC motors. Motor has some torque constant which tells how current converts to torque. I.e. 1A current will always produce a equal amount of torque with same kind of motors. Drive doesn’t need to know how much torque that actually is, as long as it stays somewhat constant over time.

Night brings counsel!

I understood that we seek for torque control

It is not a physical value on the motor shaft but better stability no matter the value of Nm on the motor shaft

I think I want to go looking too far on simple things ^^

One feature that would make your drive very appealing, even for marketing proposes is the auto-tune of the torque, velocity and position controller values, that can be seen on high market drives.

This however should only be done after you polish the current issues.

As far as I know, with your current granity implementation, it should not be difficult to implement an algorithm that would collect and process the torque response until a “optimum” value is achieve. As there are only a few variables, the algorithm should not be to much complicated to implement.

The same would then be done to the velocity and position settings.

You would have to manage when the drive enters in error in an automatic way, as the user would only need to start the test and wait.

This would be a very nice feature, that could be trick to implement, but would give to the user a faster installation procedure, or if slower, less boring/intense try and error approach (even you will receive less “tickets” about the settings).

Indeed! That is definitely something we also want. I have prototyped torque control tuning and it works quite nicely already. However, sometimes it misses the good gain values which should be somehow eliminated as it could only make things worse.

Please let me know if you’re looking for a article author for your site.

You have some really good articles and I feel I would be a good

asset. If you ever want to take some of the load off, I’d absolutely love to write some content for your blog in exchange for

a link back to mine. Please send me an email if interested.

Cheers!

my website: where can i buy deer antler velvet spray (http://Www.Greenenergysystems.Co.kr)