A day in a EMC lab yielded over 40 radiated emission measurements and lots of useful data about how to install the device to minimize interference.

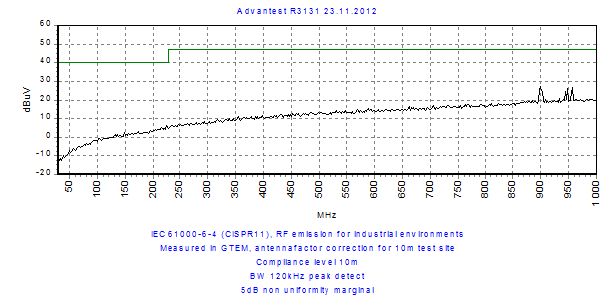

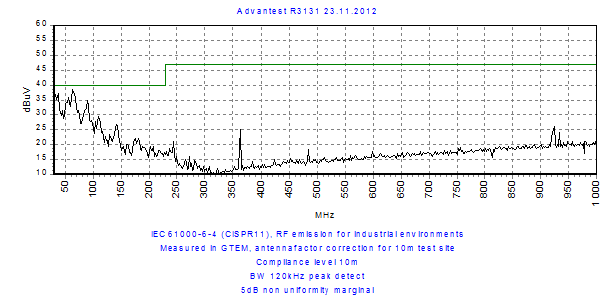

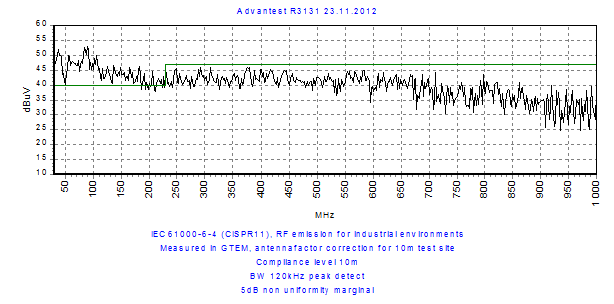

Few radiated emission test results shown below. The green line represents the limit to meet IEC 61000-6-4 limits in industrial environments, so any spike above it would mean that device is not compliant.

Chamber & measurement equipment background noise. The small spikes in GSM frequencies can be seen beyond 900 MHz. Notice that graph has different scale than the ones below.

These tests were carried out while drive was executing 10 Hz high current square wave torque command which was found to produce the worst case scenario.

By experimenting we found out that a ferrite bead core on 3-phase output leads (as common mode filter) before motor cable makes a quite significant difference. The graph below shows a success in emission test. This test was repeated several times in different ways to eliminate the possibility of error.

Same as above but with a ferrite bead filter on phase leads. A spike visible at 360 MHz is probably a third harmonic from the 120 MHz CPU.

In addition to emission tests, also radiation immunity test was carried out. No sign of disturbance was noticed on drive operation or communication to PC, so immunity test was passed as well.

Next up: ESD & EFT tests. But first I’m going to visit Germany and SPS IPC DRIVES fair in Nuremberg. See you there!

Looks pretty good. We had the same problem in the past – testing an electrical cabinet containing a VSD-E-160. The sollution was a low pass filter on supply side of the cabinet.

Do you plan to test the Argon for light industrial environment or for home use? The levels are quite lower in this case and it’s more difficult to pass the test.

See you in Nuremberg!