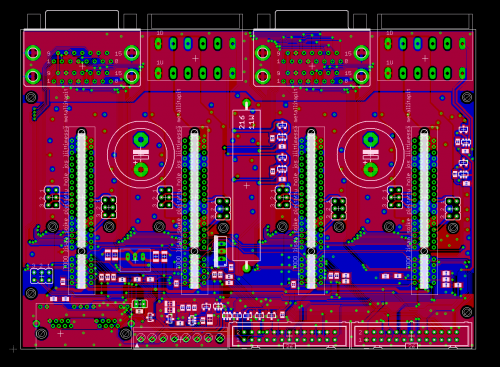

Despite of being quiet, we have not been resting all summer. The four axis motherboard for ION drive is only pending “proofreading” and last minute ideas before prototyping.

The solution here is to use PCI-express 8X connectors where extra pins may be used later for higher power drive. The first ION model has PCI-e 4X connector and plugs in 8X socket too.

The board has been designed to be ideal solution for CNC, 3D printing and custom motion control systems. Key features include:

- Carry up to 4 ION drives

- On-board regenerative braking resistor

- Each axis can have mechanical end switches and homing switch

- Motor holding brake drivers for each axis

- The first 26 pin ribbon cable connector is laid out so that it’s directly connectible to traditional CNC controllers (parallel port, SmoothStepper etc).

- The second 26 pin connector has extra I/O for drives and analog setpoint inputs for custom applications

- No separate break-out-boards needed

- Charge-pump input for safety

- E-stop switch input (safe torque off)

- PWM to 0-10V converter for VFD spindle

- Two relay drivers

- Argon compatible encoder connector pin-out

- RJ45 connectors for SimpleMotion V2 usage and configuration

- Address selector jumper: up to 4 boards can be chained in one SMV2 bus (total 16 axis)

Any further ideas welcome! There’s still time to add more in it :)

Thanks for the hard work in the summer time!

Is “MACH 4″ via RJ45 usable?

Best Regards

Klaus (Herford)

I’m dreaming of community driven open source project for SimpleMotion Mach4 support. I’m looking forward starting and coordinating that project once Mach4 is out. It is definitely the way to go after step/dir era.

This is excellent!

Almost everything on my wish list is here. Very pleased to see the onboard regen resistor and 0-10v output! There’s two additional features in particular I’d really want:

I agree with Klaus, support for Mach4 via ethernet would be a high priority to me. Direct connect parallel port support was an excellent feature on the VSDEPI and will be just as useful here. However, fewer and fewer PC motherboards have even a header for the parallel port these days. A smooth stepper is always an option but it’s a significant extra cost when in many cases the only reason it’s needed is because the PC lacks a parallel port.

An onboard relay would also be much appreciated – I made use of the relay on every VSDEPI installed.

If we could have these two features, the drive cabinet could be super clean, only needing HV and logic power supplies.

Best regards,

Jason

Thanks for useful feedback, Jason!

I’ll see if we can fit a relay in it (it takes more pins in terminal and there’s not lots of space for wider connectors). However, having relay driver outputs might give more freedom (can use large contactors, solid state relays etc).

Hi Tero,

I have another long-shot idea for you but don’t know whether it would be practical or useful to others besides myself. It would be nice if the encoder inputs were configurable so that encoders such as Renishaw LM and RGH series could connect without rewiring the standard plug.

Best regards,

Jason

I quickly checked the pin-out of RGH. It seems to be quite much different to what we use so any software solution is not possible. If you need to use them a lot, then making a small converter PCB might save time. Such adapter could be just a tiny piece of PCB with two D15 connectors and wiring of signals to another pins.

It’s really a pity there isn’t any De facto standard for encoder connectors.

I like the idea of a PCB converter board; I would only add consider making one that will fit into a DSub gender changer backshell (such as a Norcomp 957-009-xxx DB9 or 957-015-xxx DB15 sized).

If you just need to make a couple converters, another approach is to use the gender changer backshell with a pair of D-Sub M/F connectors (solder or crimp) and just wire it up – I’ve just this approach myself with HD15M/F crimp connectors.

Thanks Tero, that’s an excellent idea. Tony – that’s a brilliant idea to use the gender changer housing! I’ll do that.

Regards,

Jason

I also love the idea of fitting it in gender changer cover. If people are willing to share the converter designs, I will gladly put them in a dedicated page of Wiki. Just drop me an email.

PCB’s are dirt cheap nowadays, I have many times used this service (~$1 per PCB):

http://imall.iteadstudio.com/open-pcb/pcb-prototyping/im120418001.html

I need the ability to daisy chain motherboards for 5-6 axis machines.

It’s already there :)

Whoa 16 axis, that’s awesome.